As a recycled plastic supplier, we are often asked what can be manufactured with recycled polystyrene pellets. Our answer is always the same: just about anything! Polystyrene pellets are a highly versatile material that can be used to create a wide range of products. In this blog post, we will discuss some of the most common uses for recycled polystyrene pellets and what makes them such an important part of the international manufacturing process.

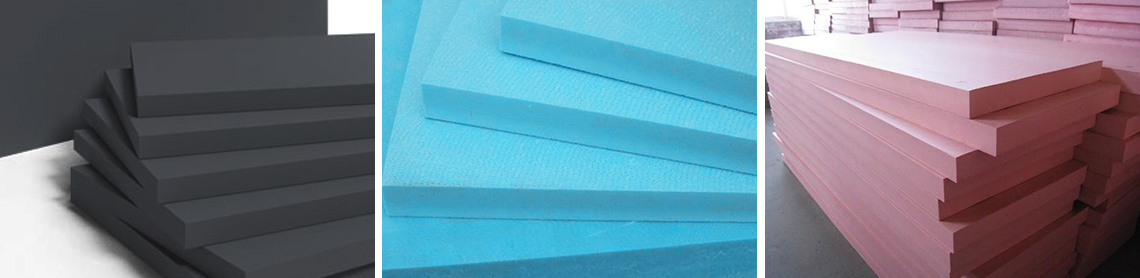

Many construction panel factories choose recycled polystyrene raw materials as one of materials to produce XPS boards which manufactured is featured by impact resistance, noise resistance, heat preservation, moisture resistance, safety, cleanness, blister plasticizing capability and etc. Due to its high cleanliness and high purity, recycled GPPS is very popular, providing cost effective high performance solutions in building and construction industry.

In addition to being used in the manufacturing of XPS boards, polystyrene pellets are also commonly used to create the soles of shoes. These lightweight and durable polystyrene soles offer excellent protection against impact, making them an ideal choice for athletic shoes and outdoor footwear. This means for businesses looking to sell footwear, you can produce quality products designed to last. And this will help generate a loyal customer base.

Polystyrene pellets are also commonly used in the production of textiles. Whether it is used to create polyester fibers, polythene sheets, or polypropylene yarns, polystyrene pellets can be incorporated into a wide range of textile products. This can help your business to become more sustainable by working with a recycled plastic supplier rather than sourcing new materials to make textiles for the home.