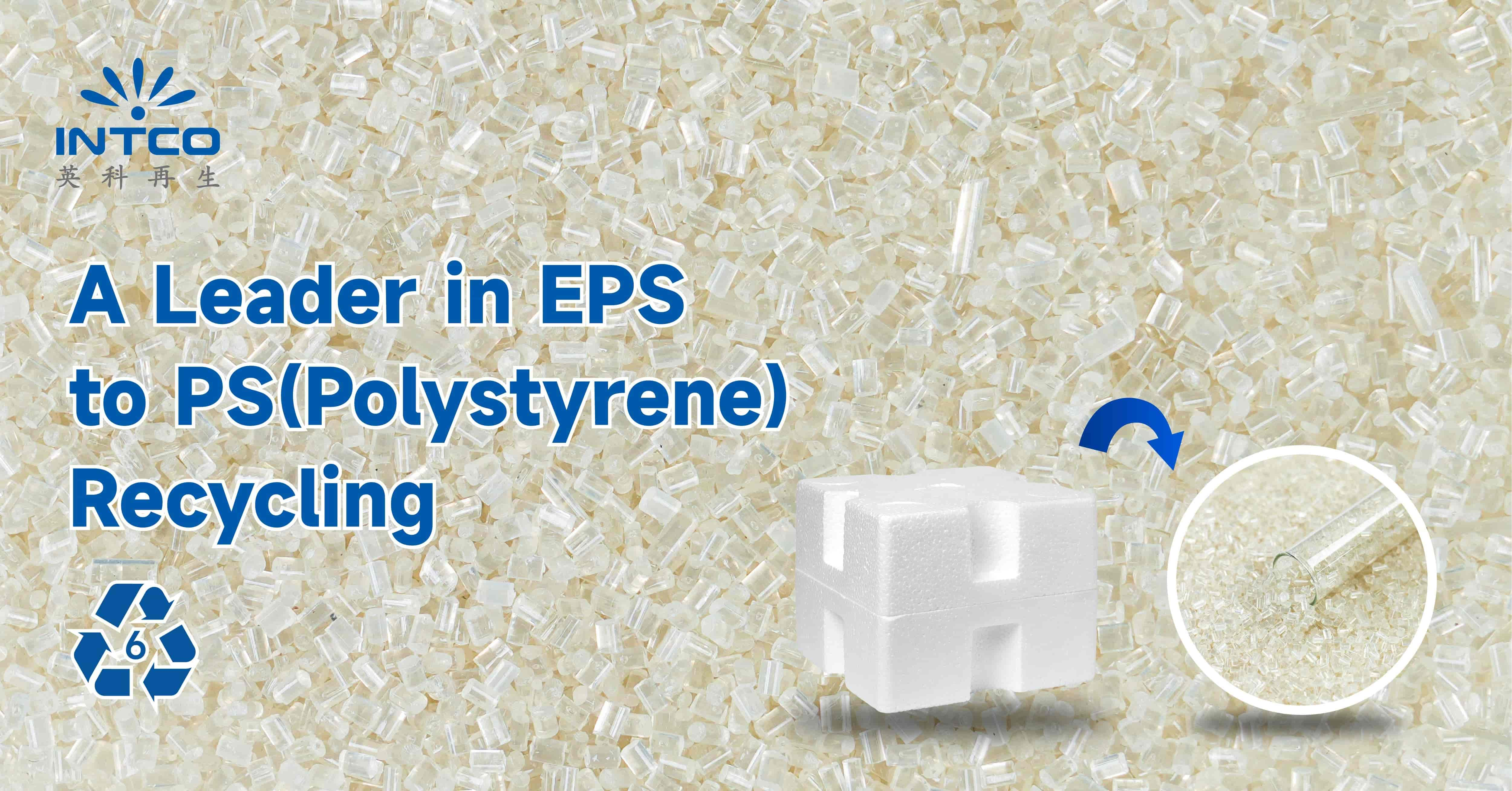

The push for sustainability in manufacturing has led to the increasing adoption of recycled materials. Among these, recycled General Purpose Polystyrene (GPPS) pellets have gained prominence due to their versatility, cost-effectiveness, and eco-friendly benefits. Recycled GPPS pellets are used in a variety of modern industries, helping businesses reduce their environmental footprint while maintaining high-quality production standards. Let’s explore the key applications of recycled GPPS pellets in today’s industries.

- Packaging Industry

The packaging industry is one of the largest consumers of GPPS pellets. Recycled GPPS pellets are used to manufacture:

-

Disposable food containers: These include trays, cups, and lids that are lightweight, durable, and cost-effective.

-

Protective packaging materials: Such as cushioning inserts and clamshell packaging for electronics and fragile goods.

The transparency and rigidity of GPPS make it an excellent choice for applications where product visibility and protection are priorities.

-

Electronics Industry

In the electronics sector, recycled GPPS pellets are utilized to create components like:

-

Housings for small appliances: Their insulating properties and ease of molding make them ideal for lightweight casings.

-

Protective casings for electronic devices: Offering durability and aesthetic appeal without compromising functionality.

This use not only reduces costs but also supports sustainability goals within the electronics manufacturing supply chain.

-

Construction Industry

Recycled GPPS pellets find applications in the construction sector, particularly for producing:

-

Insulation boards: These provide thermal efficiency while being lightweight and cost-effective.

-

Decorative panels and moldings: Offering aesthetic versatility without adding significant weight to structures.

By integrating recycled GPPS materials, the construction industry can reduce its reliance on virgin plastics, promoting greener building practices.

-

Automotive Industry

The automotive industry leverages recycled GPPS pellets for various non-structural components, such as:

-

Interior panels: These are lightweight and easy to customize.

-

Small accessories: Including holders, trim pieces, and decorative elements.

The use of recycled GPPS helps manufacturers meet stringent environmental regulations while reducing production costs.

-

Consumer Goods

-

Household items: Like storage boxes, organizers, and disposable utensils.

-

Toys and novelty items: Lightweight, safe, and easy to manufacture.

Their affordability and adaptability make recycled GPPS pellets a popular choice for mass-produced items.

Benefits of Using Recycled GPPS Pellets

-

Cost-Effectiveness: Recycled GPPS pellets are more affordable than virgin plastics, reducing overall production costs.

-

Environmental Sustainability: By reusing materials, industries can significantly lower their carbon footprint and reduce plastic waste in landfills.

-

Versatility: Recycled GPPS pellets retain many of the properties of virgin GPPS, making them suitable for a wide range of applications.

-

Compliance with Regulations: Using recycled materials helps businesses meet environmental standards and sustainability targets.

Conclusion

Recycled GPPS pellets have emerged as a vital component in modern manufacturing. From packaging and electronics to automotive and medical supplies, their applications span numerous industries. By integrating recycled GPPS into production processes, businesses not only achieve cost savings but also contribute to a more sustainable future. As recycling technologies advance, the potential for recycled GPPS pellets to transform industries will only grow, making them a cornerstone of sustainable innovation.

INTCO Plastics stands out as a leader in the recycled GPPS pellets market, offering unparalleled advantages:

-

High-Quality Standards: INTCO ensures consistency and superior quality in every batch of recycled GPPS pellets.

-

Eco-Friendly Processes: Their advanced recycling technology minimizes environmental impact, aligning with global sustainability goals.

-

Customizable Solutions: INTCO provides tailored GPPS pellets to meet diverse industrial needs, ensuring versatility across applications.

-

Global Expertise: With extensive experience, INTCO supports industries worldwide with reliable, innovative, and cost-effective solutions.